HOW TO MAKE ARTISAN ICE CREAM - TRADITIONAL SYSTEM VS MODERN SYSTEM

Below, we explain the process of making a traditional artisan ice cream vs the modern system.

(A) TRADITIONAL SYSTEM 8 – 10 HOURS.

1. THE INGREDIENTS: Selection and dosage (15-20min)

Ice cream is the result of a sum of ingredients and a meticulous production process, the final product will largely depend on the quality of the products we use. We must be demanding in the ingredients so that they are as natural as possible, local if feasible and always of high quality and adapted to the tastes of our consumers.

The weighing and dosing of the ingredients is the first step in the production process, it is important to be rigorous and methodical to avoid errors that may affect the final result. It is recommended to use a production sheet to follow the correct order of dosage and we must have the help of a precision balance.

2. PREPARATION OF THE MIX. (10-15min)

Once we have all the ingredients of the mix ready, we must go to the second step of the process: mixing and dissolving the ingredients. It can be done directly in the pasteurizer or a large container by first incorporating the liquid ingredients (milk, water, cream, etc.) and then the solid ingredients (powdered milk, sugars, cocoa, fruit, etc.). The ingredients will be incorporated with the hot mix, starting at 30º to favor its dissolution, the solid ingredients such as chocolate, dried fruit pastes, etc., will need higher temperatures (up to 70ºC) for their correct dissolution within the mix.

We will reserve some ingredients for later, avoiding thermal shock, in order to preserve their organoleptic characteristics that could be affected by high temperatures. These ingredients must have already been pasteurized previously.

3. PASTEURIZATION AND MATURATION OF THE MIX (8-10h)

Pasteurization is known as the thermal process by which the temperature of the mixture is raised for a period of time in order to reduce the population of pathogenic microorganisms and thus reduce any risk for human consumption. The pasteurization used for the production of ice cream uses relatively low temperatures and times, achieving an extension of the shelf life and preserving the nutritional value and the organoleptic qualities of the ingredients.

Once the pasteurization stage has elapsed, we must proceed to stop the thermal shock and bring the mixture to a temperature between 2 and 5º to later let it rest for a period of between 6 and 8 hours. This is known as the maturation of the mix, and it is a step that not everyone follows in order to shorten the manufacturing process. It is advisable? The answer is: yes, because in this way we achieve that the proteins and the rest of the ingredients are properly hydrated and the stabilizers have their effect. Without this maturing process, the ice cream could have deficiencies: ice crystals can form, it can fall apart faster, particles of undissolved ingredients can be found, etc.

4. BATCH FREEZING (10-15min)

It is the process by which we go from a liquid mixture to a semi-solid state through the application of cold and with stirring that will help us to incorporate air. In artisan ice cream a machine called a batch freezer is used, which is the one that will carry out this process between 8 and 15 minutes. In the market there are numerous options and it is important to select this element correctly, we must always size according to our needs. It is important to bear in mind that the freezer is going to be the engine of our business, and it implies one of the important investments to be made.

5. ICE CREAM COMPLEMENTS

When leaving the batch freezer, the ice cream is at a temperature of between -8ºC and -12ºC, this is the moment when other elements can be incorporated (fruit or chocolate sauces, pieces of cookies, pieces of nuts, etc.) and they can be mixed since the texture and creaminess of the ice cream allows it. These ingredients are incorporated correctly, giving the ice cream a special personality.

6. ULTRA FREEZING OF ICE CREAM

Once we have the finished ice cream, we go to the deep freezing process, lowering the temperature to at least -22ºC at the highest possible speed. The objective is that the water microparticles contained in the ice cream crystallize as quickly as possible so that they are unnoticeable on the palette, and to maintain all the air incorporated in the freezing process (between 25 and 35%) so we do not lose volume.

The element that will help in this process is a blast chiller, which is one of the most important machines in the ice cream making process. There are also numerous manufacturers on the market and we must know how to correctly choice the right size for our production needs.

7. PRESERVATION AND SALE OF ICE CREAM

For the packaging and conservation of the ice cream we will use tubs or containers suitable for food use, clean and disinfected. The conservation of ice cream must be at least below -18ºC and in a freezer that does not have many temperature variations, any variation can lead to the appearance of ice crystals. To keep the ice cream for a long period of time without affecting its structure too much, we should keep it at a temperature of -24ºC.

The best way to sell ice cream is by putting it in a display case that allows us to show its textures, its colors, its ingredients, etc. The exposure temperature can range between -12ºC and -18ºC and the ice cream must be correctly formulated to withstand its structure in this hostile environment (light, air, humidity and changes in temperature). Inevitably in the display case the ice cream will lose its properties, it is advisable whenever possible, when the store is not open, to store in a freezer cabinet at -18ºC

(B) HOW TO MAKE AN ARTISAN ICE CREAM Easycream © method - 11 mins

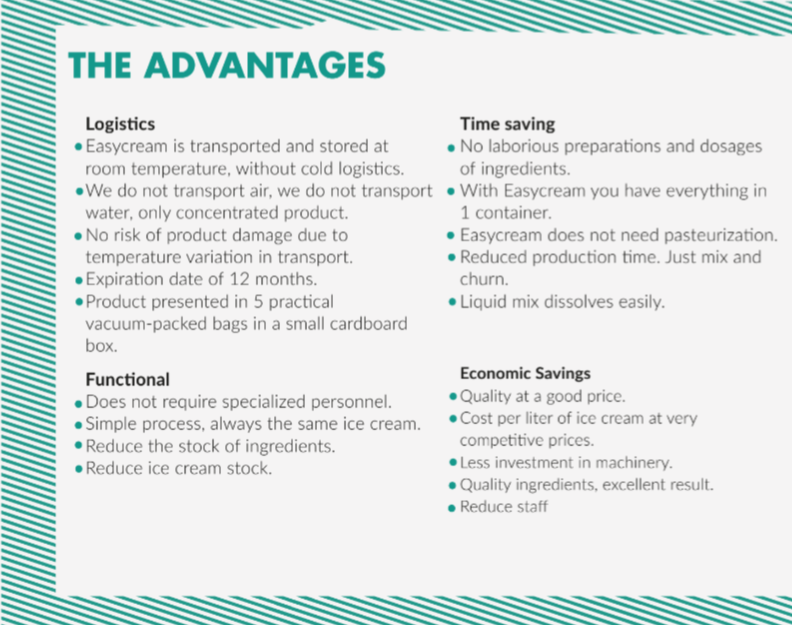

At Gelato Manufacturing we have developed an innovative product to simplify and shorten the processes of artisan ice cream making. A mix to make artisan ice cream of the highest quality in a only a few minutes! This product is called Easycream©, which is a concentrated mix for making ice cream that only needs to be hydrated (with water or milk) in a batch freezer to achieve an ice cream of exceptional qualities.

Do you want to incorporate artisan ice cream into your business? Discover our range of ice cream bases and other products for ice cream parlors.

Our EASYCREAM © gel bases are very easy to use to make fresh artisan ice cream. We have more than 30 flavors of ice cream and we can adapt our products to the tastes or preferences of our customers. Our mixes are perfect for ice cream parlors that want to simplify their operations and have an extraordinary ice cream!

+34 651 666 439

+34 651 666 439